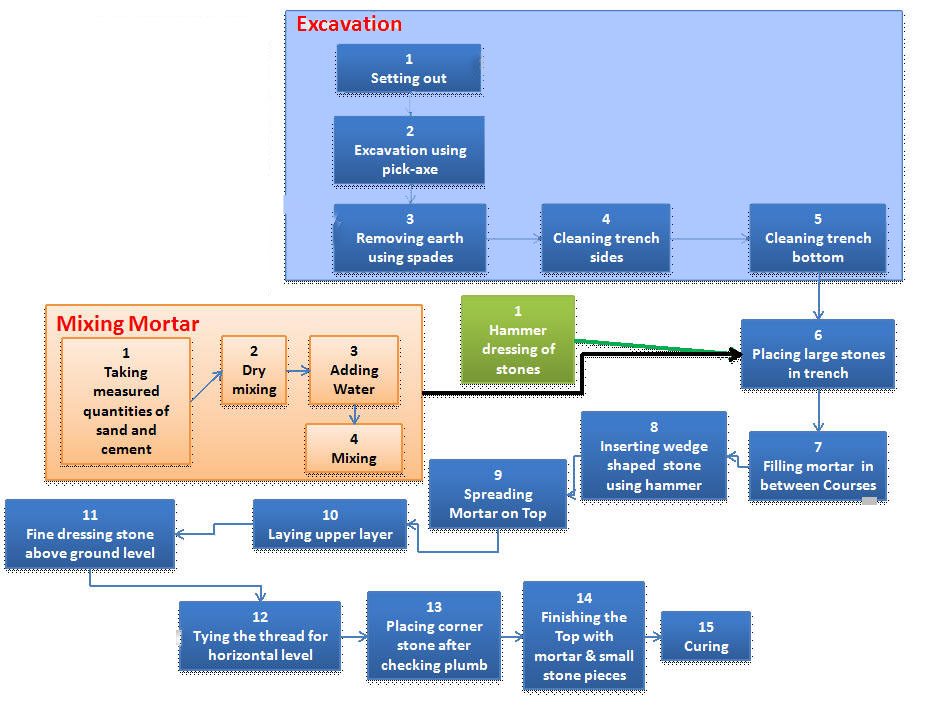

Stone Masonry Foundation

The place where stone is in abundance or in rocky or hilly terrains, the brick may not be viable solution for foundations. Therefore brick is replaced by stone and this system of foundation works out to be cheaper, however, it is equally strong and durable and can be constructed by local mesons. A typical stone footing consist of several course of stones, the lowest course usually 2-2.5times the breadth of the wall above. A bed of lean concrete of uniform thickness is first spread over the entire length of the wall. The depth of concrete bed in normally not less than 150mm and its projection on either side of lowest course varies from 10-15mm

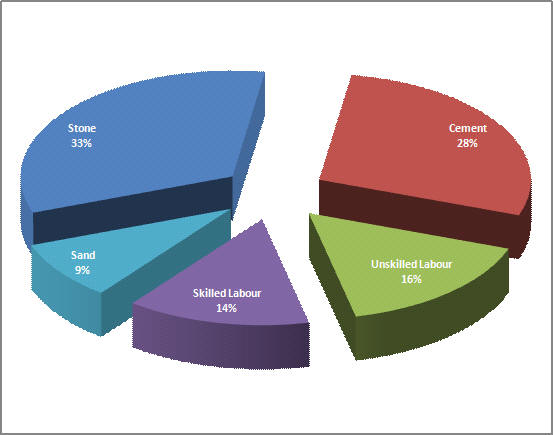

Local Economy component = 30 %

Foundation in cement mortar 1:8 of 450 x 450mm over 600 x 600 footing in hard stone (granite) from quarry

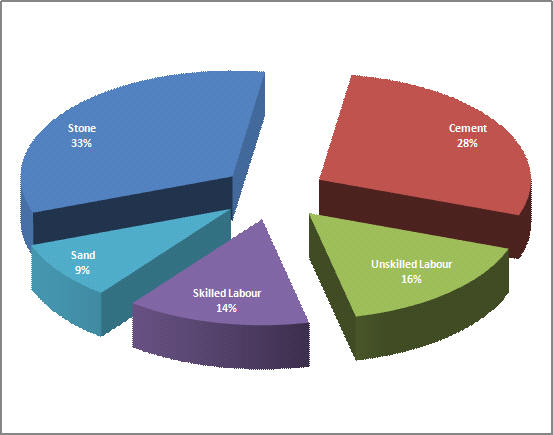

Local Economy component = 30 %

Foundation in cement mortar 1:8 of 450 x 450mm over 600 x 600 footing in hard stone (granite) from quarry

Local Economy component = 30 %

Foundation in cement mortar 1:8 of 450 x 450mm over 600 x 600 footing in hard stone (granite) from quarry

Local Economy component = 30 %

Foundation in cement mortar 1:8 of 450 x 450mm over 600 x 600 footing in hard stone (granite) from quarry