| Brick Foundation in Cement Mortar 1:8 | Brick Foundation in Mud Mortar | ||

|---|---|---|---|

| System Components | Initial Cost Structure | System Components | Initial Cost Structure |

|

|

|

|

Local Economy component = 27% |

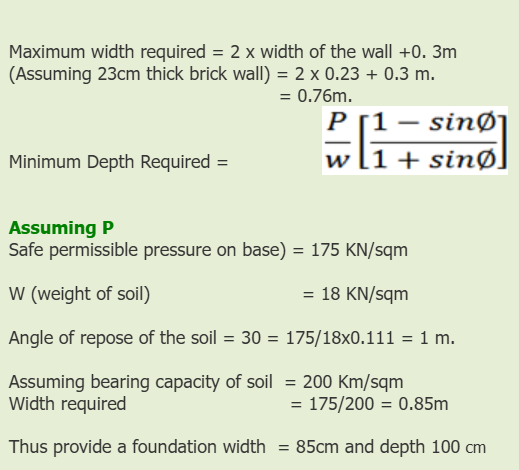

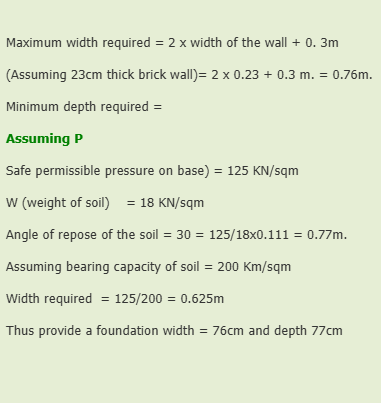

| DESIGN EXAMPLE : Foundation for a TWO storey Building | DESIGN EXAMPLE : Foundation for a single storey Building | ||

|

|

|

|

| Critical Factors | Tools Used | Critical Factors | Tools Used |

|

1. Curing 2. Width and stepping of foundation 3. Breaking of vertical joints 4. Quality of sand for mortar 5. Availability and cost of bricks |

1. Trowels 2. Plumb bob 3. Thread 4. Pans 5. Shovel 6. Pick axes 7. Baskets |

1. Quality of Soil 2. Width and Stepping of Foundation 3. Breaking of vertical joints 4. Protection from water 5. Shovel 6. Availability and Cost of Bricks |

1. Trowels 2. Plumb bob 3. Thread 4. Pans 5. Pick axes 6. Baskets |

| DO'S | DON'T'S | DO'S | DON'T'S |

| Curing of masonry should be done on seven days 1. Vertical masonry joints should be properly broken 2. Masonry should be stepped after one day's construction 3. Mortar should be used within 30 minutes of adding water to the mix. |

1. Fine sand should not be used in mortar 2. Height of masonry construction should not be more than 1m per day 3. Masonry should not be allowed to dry out quickly |

1. Soil should have medium Plasticity 2. Vertical Masonry joints should be properly broken 3. Masonry should be stepped after one day's Construction |

1. Excessively sandy and clayey soil should not be used for masonry mortar 2. Height of Masonry construction should not be more than 1m per day 3. Masonry should not be allowed to dry out quickly |

|

|

||

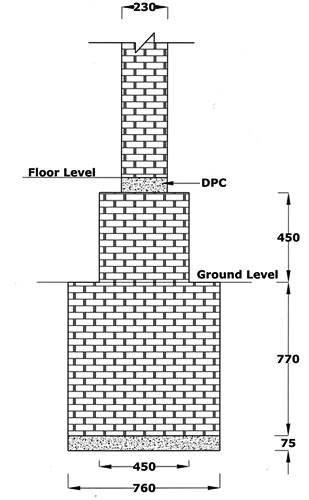

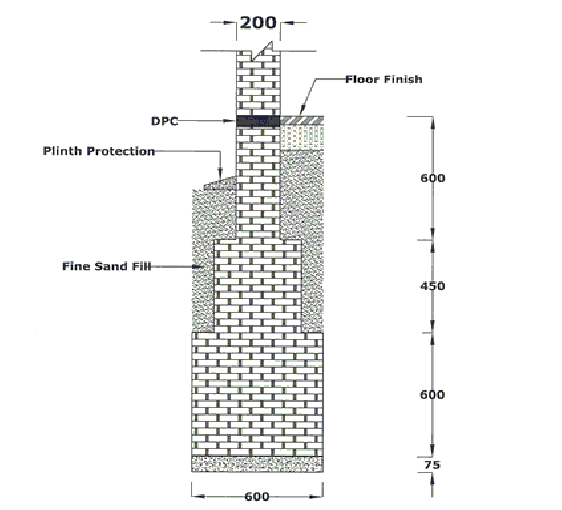

Brick Masonry Foundation

Brick Masonry Footings over Learn Cement Concrete

This is the conventional system of foundation for load bearing walls. A-100-120mm thick layer of 1:4:8 lean concrete is spread over the excavated area to get an even surface for construction of the brick footings in 1:6 cement mortar. Spread of the foundations is directly proportional to the weight of the super structure and bearing capacity of the soil.

Load bearing walls, A-100-120mm thick layer of 1:4:8 lean concrete is spread over the excavated area to get an even surface for construction of the brick footings in 1:6 cement mortar. Spread of the foundations is directly proportional to the weight of the super structure and bearing.

For typical section, click link: Conventional Masonry FoundationLearn Concrete Mix of 1:8:16 For The Base

Mixes normally used vary between 1:3:6 and 1:4:8. However, this has been found to be a rich mix as leaner mixes could be used. It has been found through actual experimental construction that cement concrete proportion as lean as 1:8:16 could be provided for base thus reducing the cost of foundation.

For typical section, click link Conventional Masonry FoundationOver-Burnt Brick Footings in Lime-Cement Mortar 1:2:12 with lean concrete base(1:8:16)

Normally in typical brick kiln, the bricks which are brunt excessively are sold at a cheaper rate as they become out of shape due to high temperatures. These brick, however, posses higher strength than the normal brunt clay bricks. Therefore one of the cheaper alternate for brick foundation is to use over burnt bricks than normal bricks. Over brunt bricks have high compressive strength between 120-150 kg/cm2. However they have very poor shape. Brick work using these bricks utilizes 40% of more mortar than traditional brick work. However this cost is offset by the price at which over burnt bricks are available.

>

>