About Roofing/ Intermediate Floors

A roof/intermediate floors is constructed to support the dead load of the roof structure and its covering, insulation and internal finishes, snow loads and pressure or suction due to wind and live load without undue deflection or distortion. In engineering parlance it is roof/floor is termed as slab.

FUNCTIONAL REQUIREMENTS OF A SLAB

Strength and stability

Resistance to weather and ground moisture

Durability and freedom from maintenance

Fire safety

Resistance to the passage of heat

Resistance to the passage of sound

Types of Roof/floor

There are several ways in which roof/floor can be constructed. Normally in India, Reinforced Concrete Floors are prevalent. However, for roofs and floors there are several options depending upon the local availability of materials such as truss roof made up of timber, steel, bamboo and covered with thatch, tiles, AC sheets etc. The other option is to make cast in-situ slab of reinforced concrete or have prefabricated roofs such as plank and joists system of RCC, ferrocement channels, brick vaults etc.

The principal types of reinforced concrete floor construction are:

(i) Beam and slab

(ii) Waffle grid slab

(iii) Drop beam and slab

(iv) Flat slab

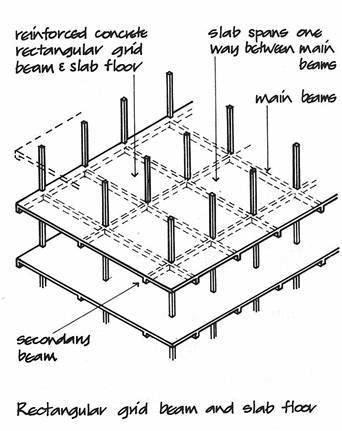

(i) Beam and slab floor

It is generally the most economical and therefore most usual form of floor construction for reinforced concrete frames. A rectangular column grid supports beams and floor floor as shown in left-hand side sketch. The floor can be cast in-situ on shuttering and form work. The floor may be formed with precast reinforced concrete floor beams, plancks, tee beams or beam and infill blocks that require little or no temporary support and on which a screed or structural concrete topping is spread. Precast beams and planck floors require no temporary support in the form of shuttering. The advantage of these precast floor systems is that there is a saving in site labour in erecting and striking the form work. The most commonly used precast floor are described below.

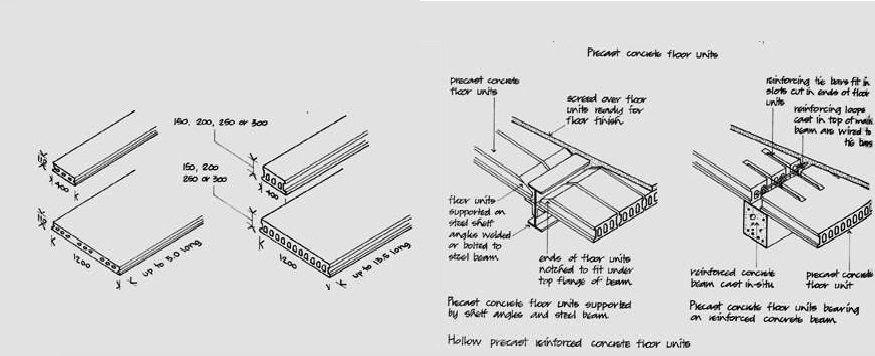

Precast hollow floor units:

These floors comprise of large precast reinforced concrete, hollow floor units of different size. The purpose of the voids or hollows in the floor units is to reduce dead weight without affecting strength. The reinforcement is cast into the webs between hollows. The hollow floor units can be used by themselves as floor slab with a floor screed or they may be used with a structural reinforced concrete topping with tie bars over beams for composite action with the beams.

The below mentioed Figure gives an typical illustration of precast hollow floor units. These are termed as precast reinforced concrete cored unit roof/floor by Indian standards.

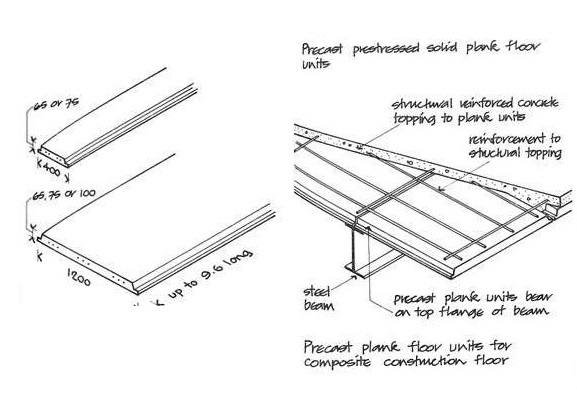

Precast concrete plank floor units:

These comparatively thin, reinforced solid plank, concrete floor units are designed as permanent shuttering and for composite action with structural reinforced concrete topping. As shown in the below illustration. It may be necessary to provide some temporary propping to the underside of these planks until the concrete topping has gained sufficient strength.

The popular concrete plank floor unit is known as precast reinforced concrete plank and joists system by Indian standards having 300mm wide planks, partially 30mm thick and partially 60mm thick with a maximum length of 1.5m.

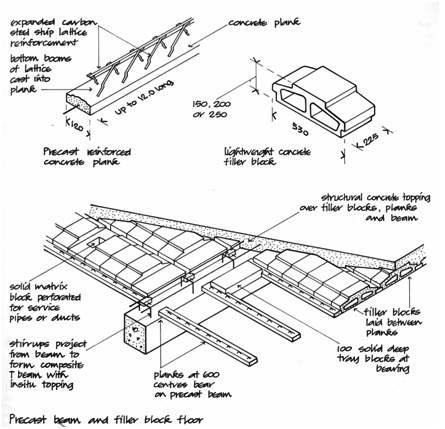

Precast beam and filler block floor :

This floor system consists of precast reinforced concrete planks or beams that support precast hollow concrete filler blocks, as shown in the illustration in the right-hand side. The planks or beams are laid between supports with the filler blocks between them and a concrete topping is spread over the planks and filler blocks. The reinforcement protruding from the top of the planks acts with the concrete topping to form a reinforced concrete beam. The advantage of this system is that the lightweight planks or beams and filler blocks can be lifted much more easily and placed in position than the much larger hollow concrete floor units

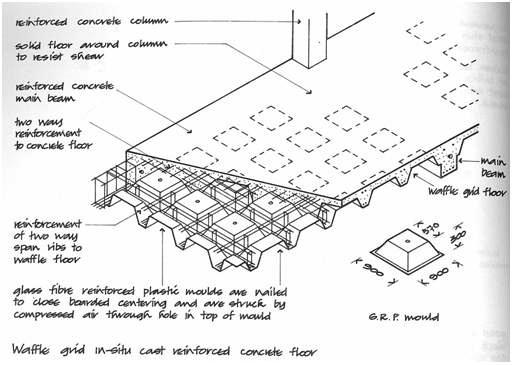

(ii) Waffle grid slab floor

If the column grid is increased from about 6.0 to about 12.0 square or near square it becomes economical to use a floor with intermediate cross beams supporting thin floor slabs, as shown in Figure. The intermediate cross beams are cast on a regular square grid that gives the underside of the floor the appearance of a waffle, hence the name. The advantage of the intermediate beams of the waffle is that they support a thin floor slab and so reduce the dead weight of the floor as compared to a flush slab of similar span. This type of floor is used where a widely spaced square column grid is necessary and floors support comparatively heavy loads. The waffle grid form of the floor may be cast around plastic or metal formers laid on timber/steel centering so that the smooth finish of the soffit may be left exposed.

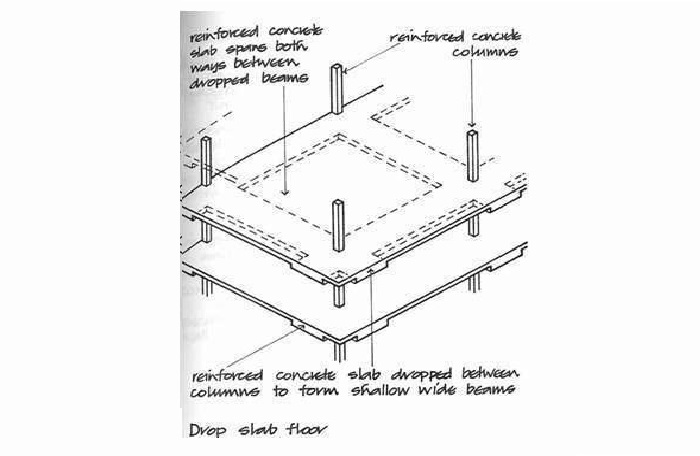

Drop slab floor :

This floor construction consists of a floor slab which is thickened between columns in the form of a shallow but wide beam. A drop slab floor is of about the same dead weight and cost as a comparable slab and beam floor and will have up to half the depth of floor construction from top of slab to soffit of beams.

On a 12.0 m2 column grid the overall depth of a slab and beam floor would be about 1.2m where the depth of a drop slab floor would be about 600mm. This difference would cause a significant reduction in overall height of construction of a multi- storey building with appreciable saving in cost.

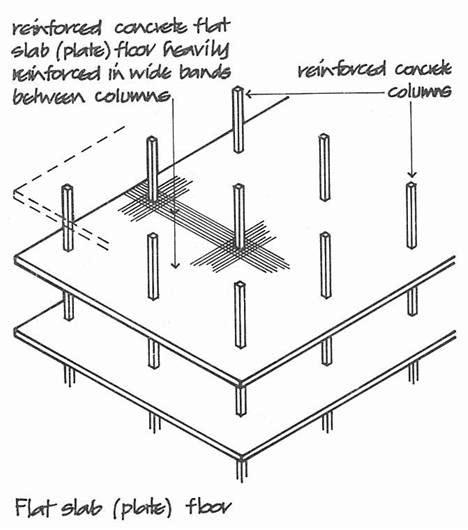

Flat slab (plate) floor:

In this floor construction the slab is of uniform thickness throughout, without downstand beams and with the reinforcement more closely spaced between the points of support from columns. To provide sufficient resistance to shear at the junction of columns and floor, haunched or square headed columns are often formed, as shown in Figure. The dead weight of this floor and its cost are greater than the floor Systems earlier explained but its depth is less and this latter advantage provides the least overall depth of construction in multi-storey buildings. The floor slabs in the floor systems described above may be of solid reinforced construction or constructed with one of the hollow, or beam or plank floor systems.

In modern buildings it is common to run air conditioning, heating, lighting and fire fighting services on the soffit of floors above a false ceiling and these services occupy some depth below which minimum floor heights have to be provided. Even though the beam and slab or waffle grid floors are the most economic forms of construction in themselves, they may well not be the most advantageous where the services have to be fixed below and so increase the overall depth of the floor from the top of the slab to the soffit of the false ceiling below, because the services will have to be run below beams and so increase the depth between false ceiling and soffit of slab. Here it may be economical to bear the cost of a flat slab or drop slab floor in order to achieve the least overall height of construction and its attendant saving in cost.